Our computer-controlled,

state-of-the-art production plant

provides a large and stable

supply of fresh concrete.

Exterior view of our state-of-the-art plant.

Raw materials are stored in silos out of consideration for the environment.

Integrated system operates under

computer control to meet the criteria of

strict quality inspections.

These are the most advanced facilities of

their kind.High-tech features are fully

utilized to produce the best fresh

concrete available.

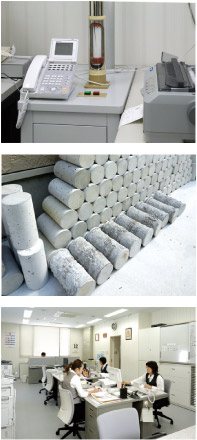

■ State-of-the-Are Laboratory

A wide variety of tests can be conducted in

the thermostatic chamber with humidity

and temperature control.

The 2000KN compression tester can accommodate

even the strongest concrete.

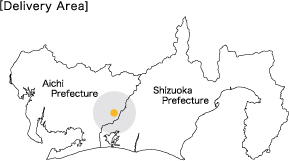

■ GPS Operation Control System

Fresh concrete trucks are equipped with GPS,

so transport conditions can be grasped in real time.

Delivery management is reduced to a minimum

for speediest arrival at delivery destination.

From left,photo shows corrugated silos for aggregate and towers for manufacturing cement and raw concrete.

Thermostatic Chamber |

Compression Tester |

Control Room |

GPS |

deliver approximately 1500m3 in a single day. |

|

Bulletin board system displays and confirms loading sequence to mixer trucks. |

■ Plant Data

・Batcher plant

・Equipped with DASH-200N 2.75m3/B mixer

・Capable of delivering approx.1500m3/day

|

|

|

|